Pottery is both a science and an art. Part chemistry, part creative imagination and part experimentation. The title of the AGGV’s new exhibition “Throw, Slip, Spin: Studio Ceramics from the AGGV Collection” might befuddle those unfamiliar with the technicalities of pottery. In this issue, we hope to elucidate upon some of these baffling terms.

1. Throw (as in “throwing pottery”)

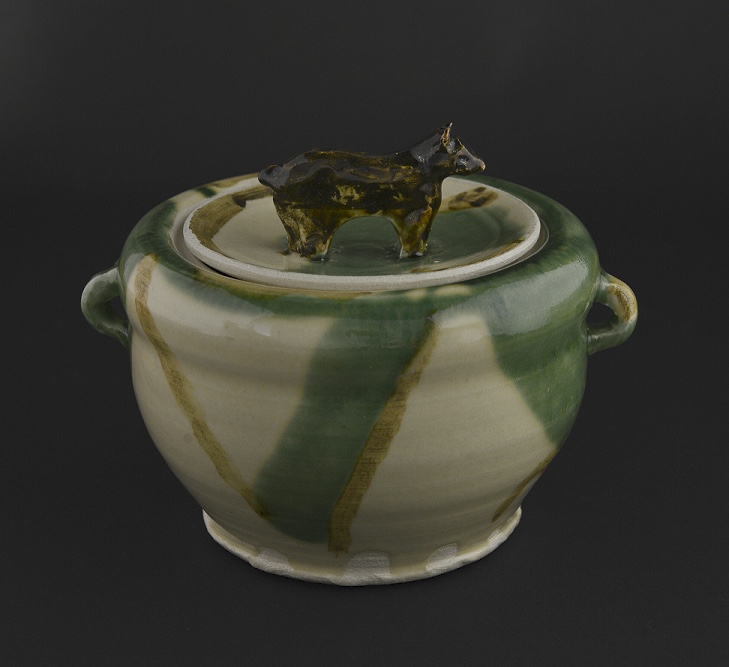

In pottery, “to throw” describes the process in which ceramic clay is turned and formed on the potter’s wheel, a device that spins to create roundness in ceramic ware. Throwing is one of the main techniques in working wet clay, the other being hand-building. The lidded pot below by Glenn Lewis was thrown on the wheel, as evident from the even concentric lines around the body.

2. Handbuilding pottery

Handbuilding pottery is one of the most ancient techniques in creating forms with ceramic clay. There are several different methods in handbuilding. These include pinching (shaping clay by compressing with the thumb and finger), coiling (rolling out clay in long ropes and coiling them upon each other to make hollow forms like pots or bowls) and slab technique (joining uniform sheets of clay to make a form).

3. Slip

A slip is a dilute clay mixture applied to the surface of a pot before it is glazed. It enhances the smoothness and helps to disguise the clay body colour if it is deemed unsuitable. A contrasting coloured slip can also be painted on the clay body to create decoration.

4. Glaze

A glaze is a clear, glassy coating applied to the exterior and/or the interior surface of a ceramic vessel. Glazes render the ceramic non-porous and may also enhance its appearance. There are several types and constituents of glaze. Silica is the main component of any glaze, making the resulting material hard and resistant to high temperatures. Silica fuses to glass at about 1700 degrees Celcius. Flux is an additive to silica to lower its melting temperature, thereby changing its characteristics. Other common ingredients of glaze may include alumina, lead oxide and calcium oxide. Each additive changes the characteristics of the glaze.

5. Underglaze and Overglaze Painting

As the names suggest, decoration can be made either under the glaze or over the top of it. Blue and white Chinese wares are a well-known example of underglaze painting whereby cobalt is painted to the body of an unfired ceramic before it is glazed. Overglaze painting is executed on top of a glaze which has already been fired. Often, the vessel is given a second firing at a lower temperature to “set” the painting.

6. Leatherhard

This term describes the state of ceramic which has been modelled into the desired shape and dried out to remove moisture from the clay. At this point, the ceramic is technically ready to be placed into the kiln to be fired.

Throw, Slip, Spin: Studio Ceramics from the AGGV Collection | February 2 – October 20, 2019 | Curated by Michelle Jacques | Pollard Gallery