In conjunction with the AGGV’s latest exhibition, Blue & White, we have selected art terms related to the art of Chinese blue and white porcelain. Several of these terms are technical and may apply to pottery and porcelain production as a whole, while some are Chinese terms and names, specific to porcelain production in China. In the case of the latter, the hanyu pinyin romanization system is used.

1. Cobalt (for pigment on porcelain)

The distinctive inky-blue pigment of Chinese blue and white porcelain is derived from cobalt oxide. The cobalt imported from Persia during the Tang dynasty (618-907) was high in iron while the local Chinese cobalt ore was higher in manganese, both creating different results in tonality. The pigment is painted onto the biscuit body before it is covered in a clear glaze and fired in a kiln at a very high temperature of between 1200 and 1400 degrees Celcius. The painting on blue and white is also known as “underglaze blue”.

2. Glaze

A glaze is a clear, glassy coating applied to the exterior and/or the interior surface of a ceramic vessel. Glazes render the ceramic non-porous and may also enhance its appearance. There are several types and constituents of glaze. Silica is the main component of any glaze, making the resulting material hard and resistant to high temperatures. Silica fuses to glass at about 1700 degrees Celcius. Flux is an additive to silica to lower its melting temperature, thereby changing its characteristics. Other common ingredients of glaze may include alumina, lead oxide and calcium oxide. Each additive changes the characteristics of the glaze.

3. Iron spots

“Iron spots” are a phenomenon found on Ming (1368-1644) imperial blue and white porcelain, formed in the cobalt pigment during the firing process. They appear as tiny spots of silvery blue-black, sometimes rust-brown, with a metallic sheen. This is caused by iron oxide in the cobalt pigment and tends to be more frequently found on the Persian imported cobalt. Later in the Qing dynasty (1644-1911), this natural effect dissipated because locally mined cobalt ore was used for pigment. To imitate the “iron spot” effect, porcelain painters deliberately added dappled points when painting blue and white patterns on porcelain.

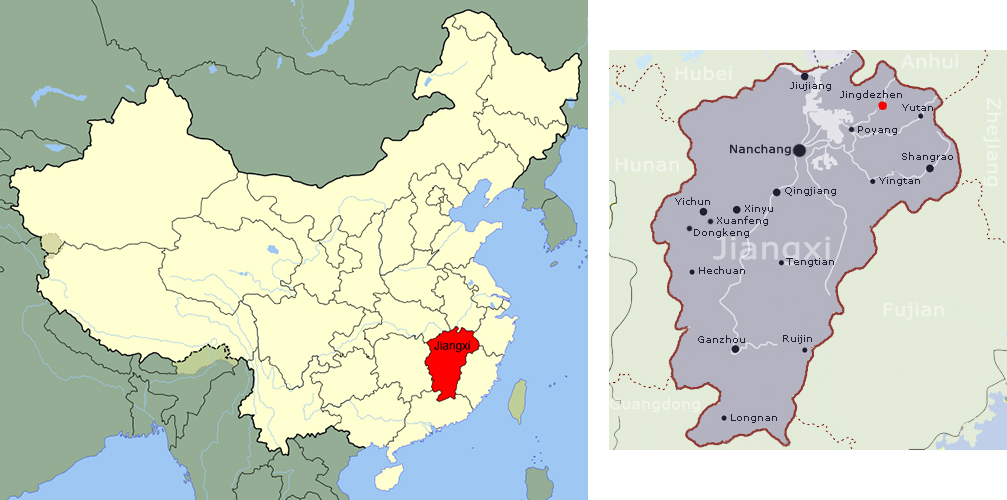

4. Jingdezhen

Jingdezhen in Jiangxi province is where Chinese blue and white porcelains have been manufactured since the Yuan dynasty (1279-1368). Production continues there today, giving it the moniker of the “Porcelain Capital” of the world.

5. Kaolin

Kaolin (also known as china clay) is the clay mineral from which the pure white porcelain body of Chinese blue and white pottery is made. The name is derived from “Gaoling”, a Chinese village near Jingdezhen where the material was used for porcelain manufacture. When made into porcelain, the material is characterized by its whiteness, translucency, considerable strength, low permeability, and high resistance to heat.

(1996.042.015)

6. Reign marks

Reign marks were painted onto the bottom of both monochrome and underglaze-blue porcelains around the time of the reign of Ming Dynasty Emperor Yongle (r. 1403-25). These were written in running script and read “Da Ming Yongle Nianzhi” (Made during the reign of Yongle of the great Ming Dynasty). Later in the Qing dynasty (1644-1911), seal marks in both underglaze and overglaze pigments were used.